Have any questions! Don't hesitate to contact us any time.

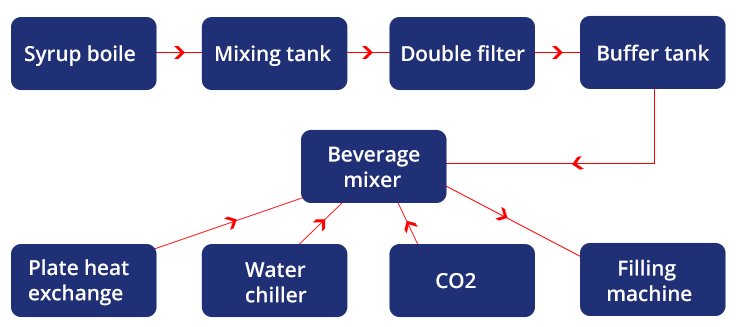

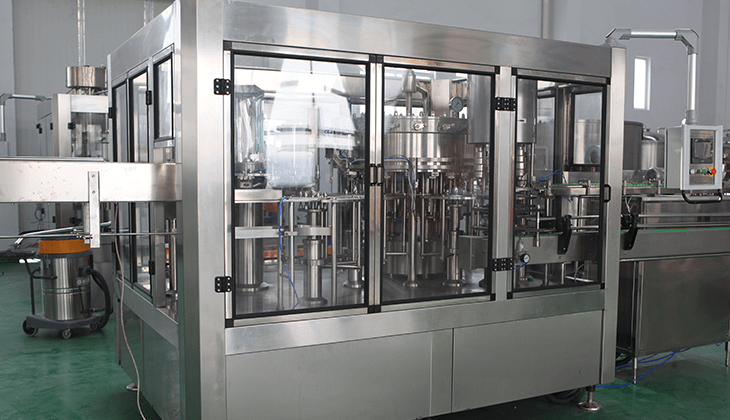

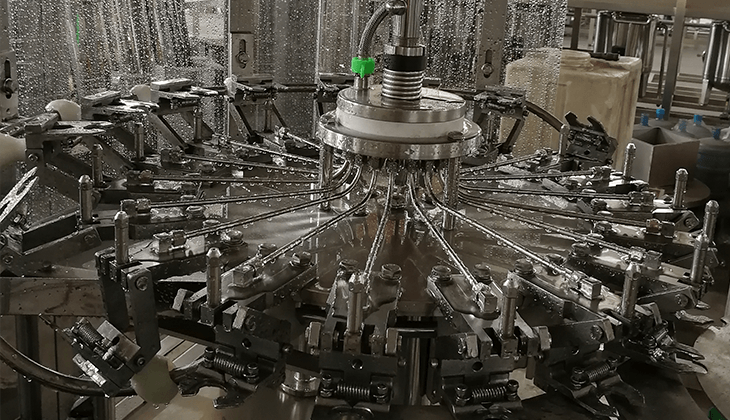

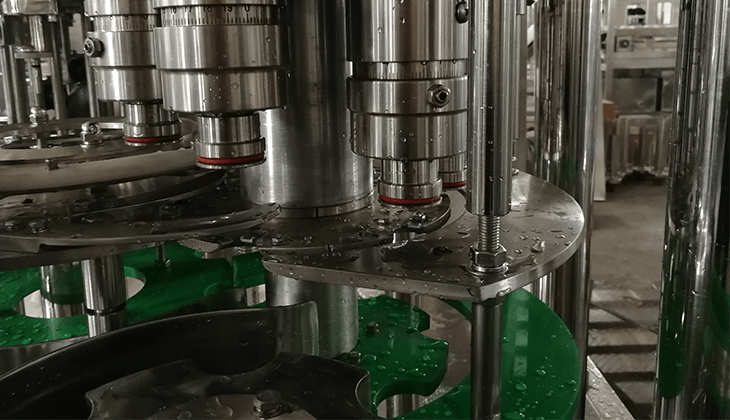

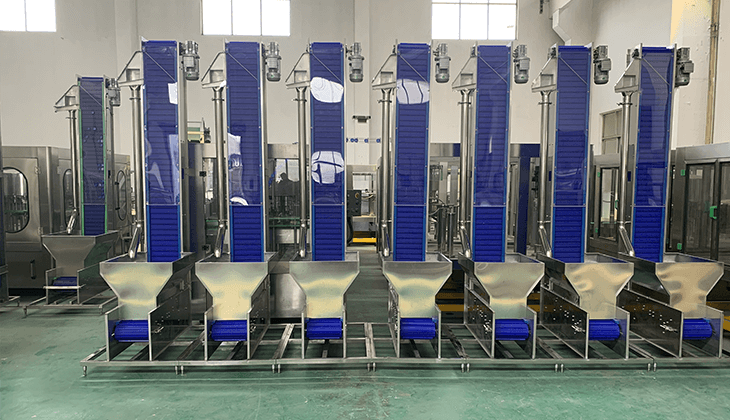

Carbonated Drink Filling Line

Carbonated drinks production began in the late 18th and early 19th centuries. The initial discovery of carbonated drinks began from sparkling spring which is gushed from natural mineral water.