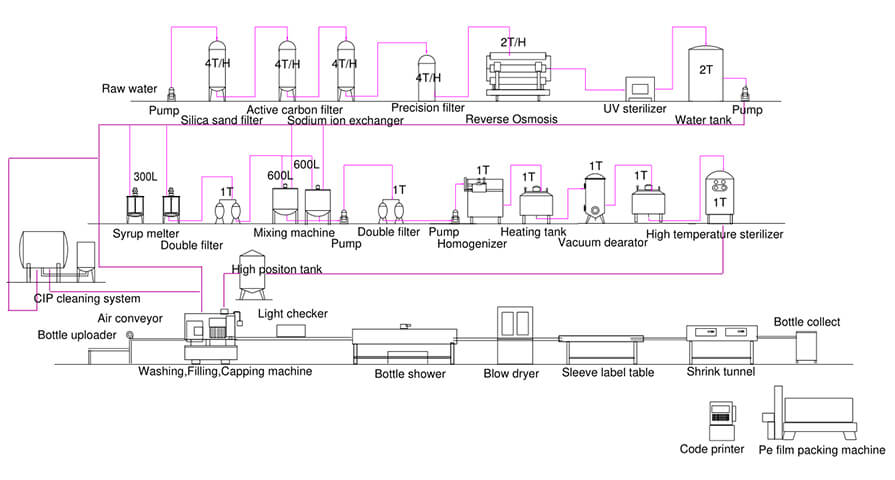

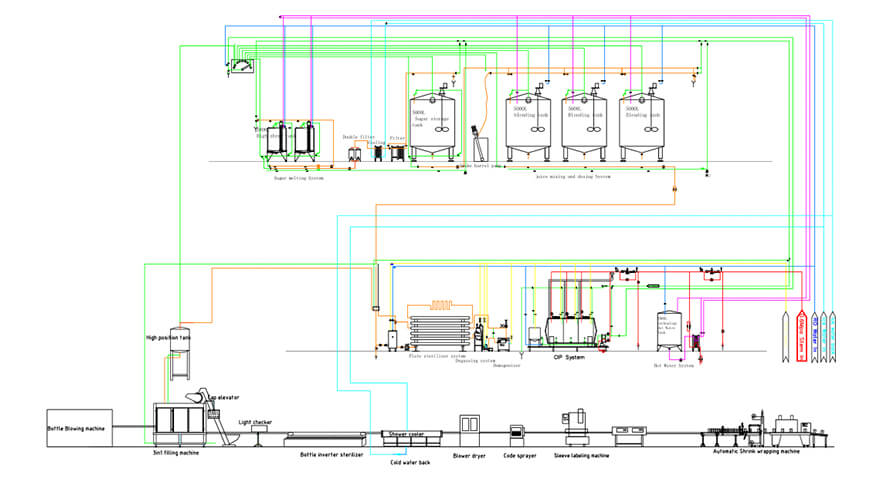

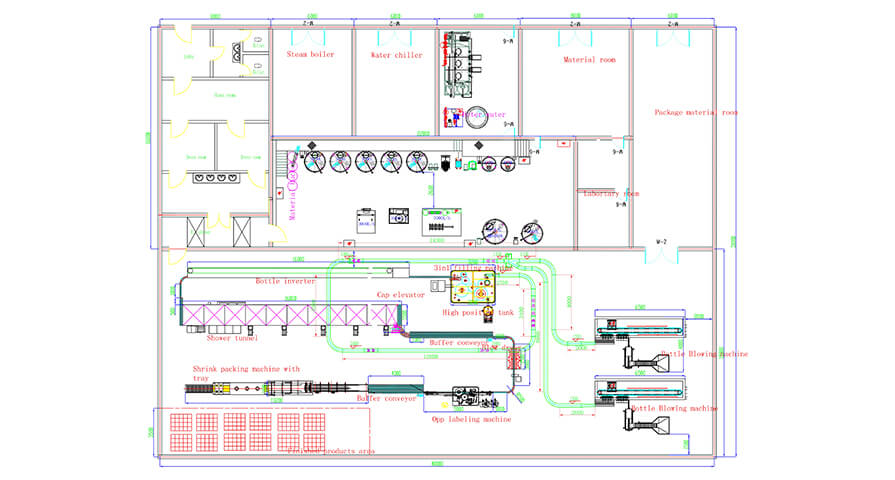

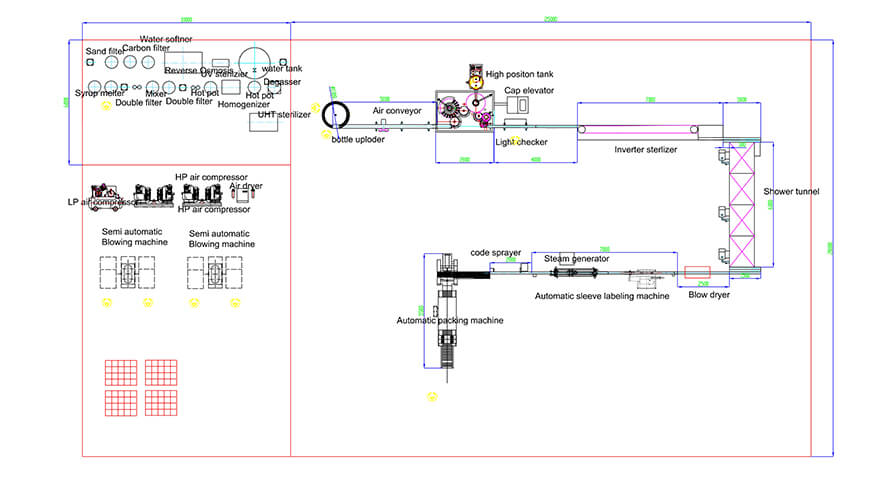

washing,filling capping 3in1 machine is mainly used in the juice filling operations. The three functions of bottle rinsing, filling and capping are composed in one body of the machine. The whole process is automatic.

3 In 1 juice filling machine

WERE THE BEST CHOICE TO KEEP YOUR JUICE FRESH!