Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

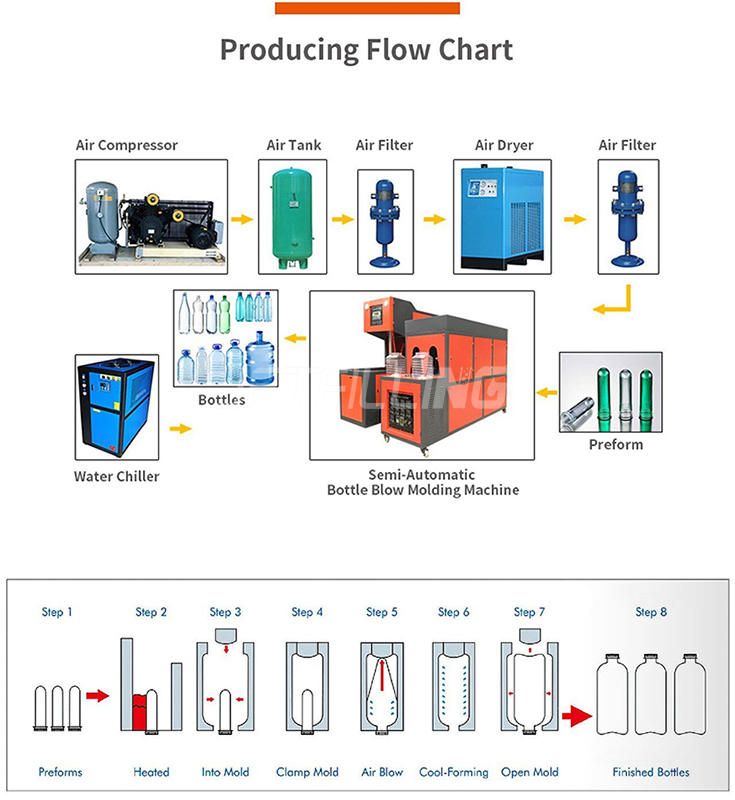

Our Semi-automatic bottle blowing machine to CE standard. Controlled by microcomputer, the technical parameters involved can be more accurately controlled. Easy to operate, safe, only need one person, no special training is required. Suitable for blowing PET as raw material of any shape of plastic containers and bottles. Widely used in blowing carbonated beverage bottles, mineral water bottles, milk bottles, oil bottles, oil bottles, cosmetics bottles, pesticide bottles, space cups and lampshades.

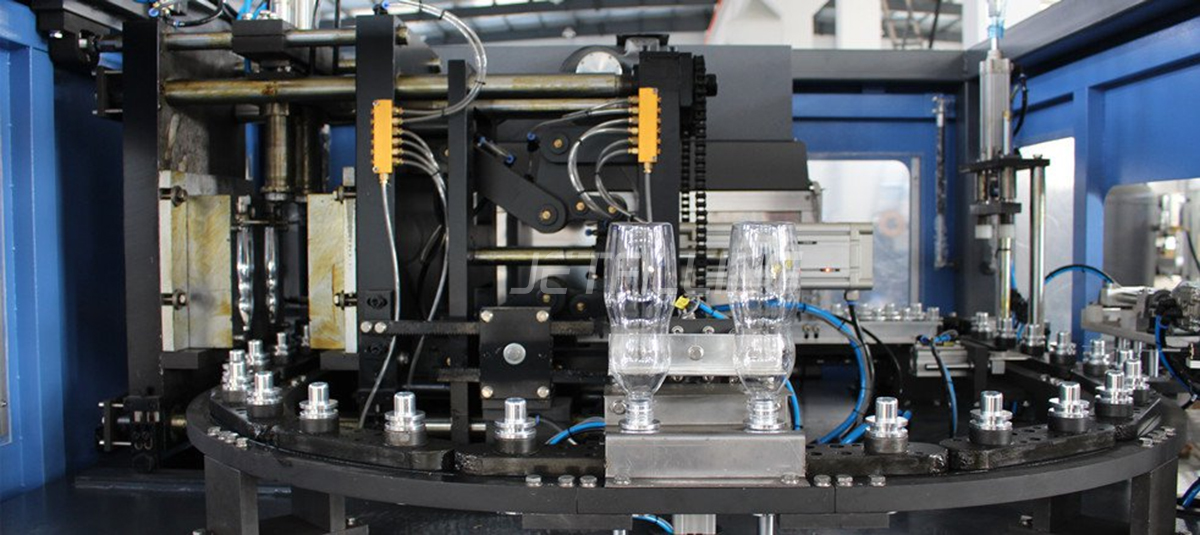

PET Bottle Blow Moulding System

Our Semi-automatic bottle blowing machine to CE standard. Controlled by microcomputer, the technical parameters involved can be more accurately controlled. Easy to operate, safe,only need one person, no special training is required. Suitable for blowing PET as raw material of any shape of plastic containers and bottles. Widely used in blowing carbonated beverage bottles, mineral water bottles, milk bottles, oil bottles, oil bottles, cosmetics bottles, pesticide bottles, space cups and lampshades.

| Technical parameter: semi blow moulding machine | |||

| Model | JET-se-2-1 | JET-se-2-2 | JET-se-4 |

| Bottle sizes | 0.1L-2L | 0.1L-2L | 1L-5L |

| Capacity(bottles/hour) | 800 bph | 1200 bph | 300~600 bph |

| Total power | 15kw | 25kw | 25kw |

| Max bottle height | <300mm | <300mm | <400mm |

| Hp air compressor | 1.0 | 1.2 | 1.2 m3/min 30kg |

| Weight | 500kg | 800kg | 1000kg |

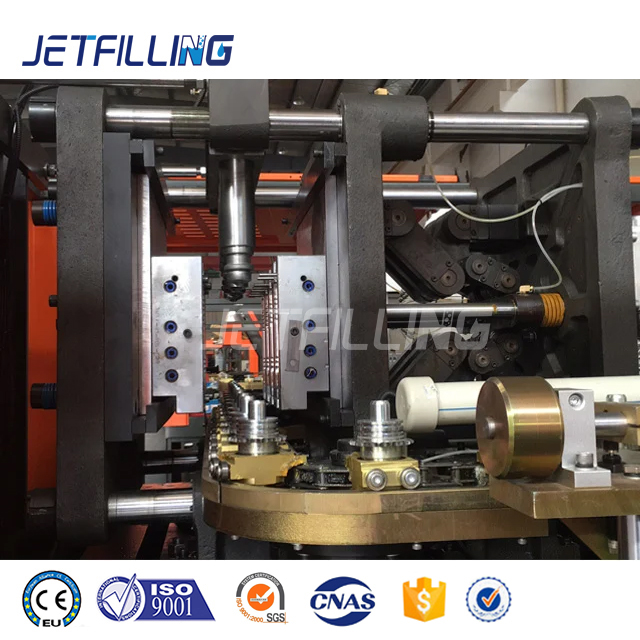

Preform Heater When the bottle embryo enters the oven, the embryo base also rotates, which can ensure that the bottle embryo fixed on the embryo base is heated evenly.Temperature affects bottle blowing effect .During testing, find the optimum temperature range for the bottle to be made. |

|  |  |

Main Features:

● Use touch screen to control the machine, convenient, efficient and durable.

● Adopting double crank to adjust mould ,heavy locking mould, stable and fast ,Adopt infrared oven to heat the perform,the perform rotated and heated equally.

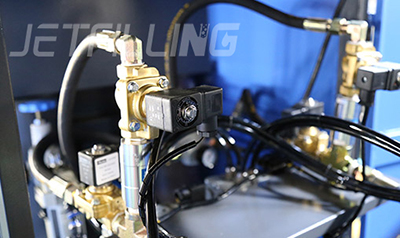

● The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements for the action and blow .It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

● The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

● The machine can be operated in the step-by-step mode and the semi-auto mode.

● The machine is small with low investment, easy and safe to operate.

|  |

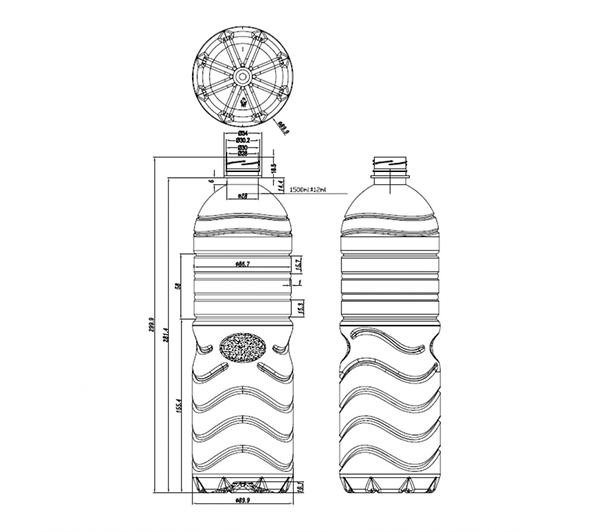

Supply bottle&label design and factory layout for free!

|  |  |

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

Factory Manufacturing

|  |

|

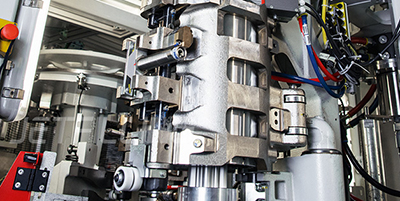

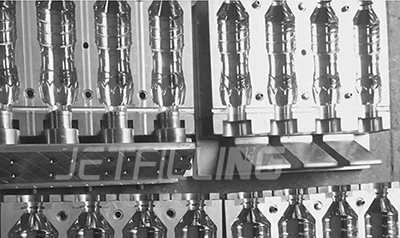

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.