Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

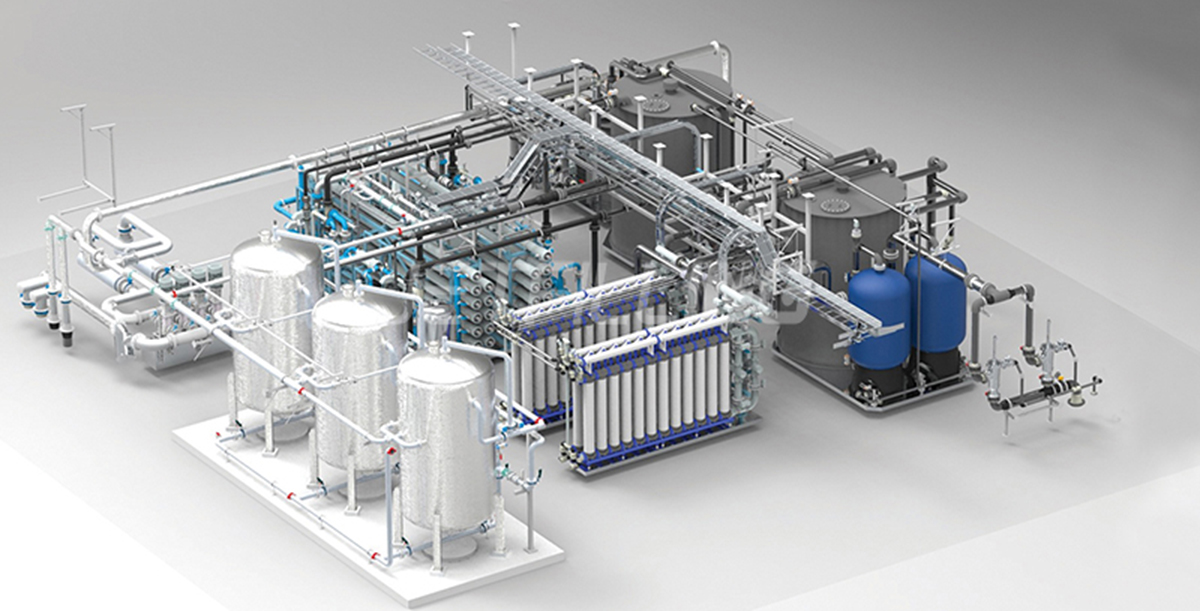

Jetfilling supplies a full line of standard and fully customizable reverse osmosis systems, all of which are engineered using advanced 3D computer modeling and process design software for accurate and customized solutions.A significant aspect for the effective running of a reverse osmosis system is the RO feedwater quality, which becomes resolved by the consistency of the water body and the success of the pretreatment process.

Product Description

RO Water Treatment System

Jetfilling supplies a full line of standard and fully customizable reverse osmosis systems, all of which are engineered using advanced 3D computer modeling and process design software for accurate and customized solutions.A significant aspect for the effective running of a reverse osmosis system is the RO feedwater quality, which becomes resolved by the consistency of the water body and the success of the pretreatment process.

Water Treatment System

| Technical Parameter: | ||||

| Capacity | Capacity (Ton Per hour) | General power | Size (L*W*H) | Weight (kg) |

| RO-500L/H | 0.5Ton | 0.75kw | 1550*900*1820mm | 350kg |

| RO-1000L/H | 1ton | 1.5kw | 1980*900*1940mm | 500kg |

| RO-2000L/H | 2ton | 2kw | 4800*700*2050mm | 700kg |

| RO-3000L/H | 3ton | 5kw | 6000*800*2200mm | 800kg |

| RO-4000L/H | 4ton | 6.5kw | 7000*900*2400mm | 1000kg |

| RO-5000L/H | 5ton | 8kw | 8000*1000*2700mm | 1500kg |

| RO-6000L/H | 6ton | 12kw | 8500*1600*1920mm | 2000kg |

| RO-8000L/H | 8ton | 15kw | 1000*1870*3000mm | 4000kg |

| RO-10000L/H | 10ton | 20kw | 12000*1700*3500mm | 4500kg |

| RO-15000L/H | 15ton | 25kw | 12500*1700*3500mm | 6500kg |

| RO-20000L/H | 20ton | 30kw | 13000*1900*3500mm | 9000kg |

| RO-30000L/H | 30ton | 35kw | 13500*2300*3800mm | 12000kg |

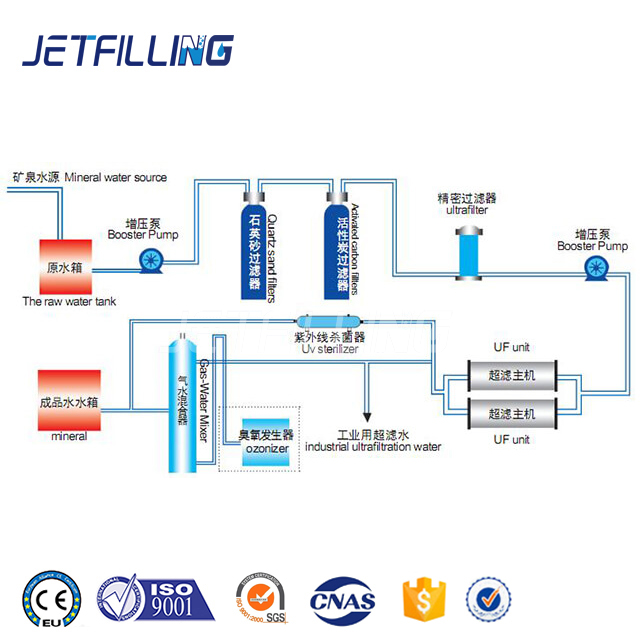

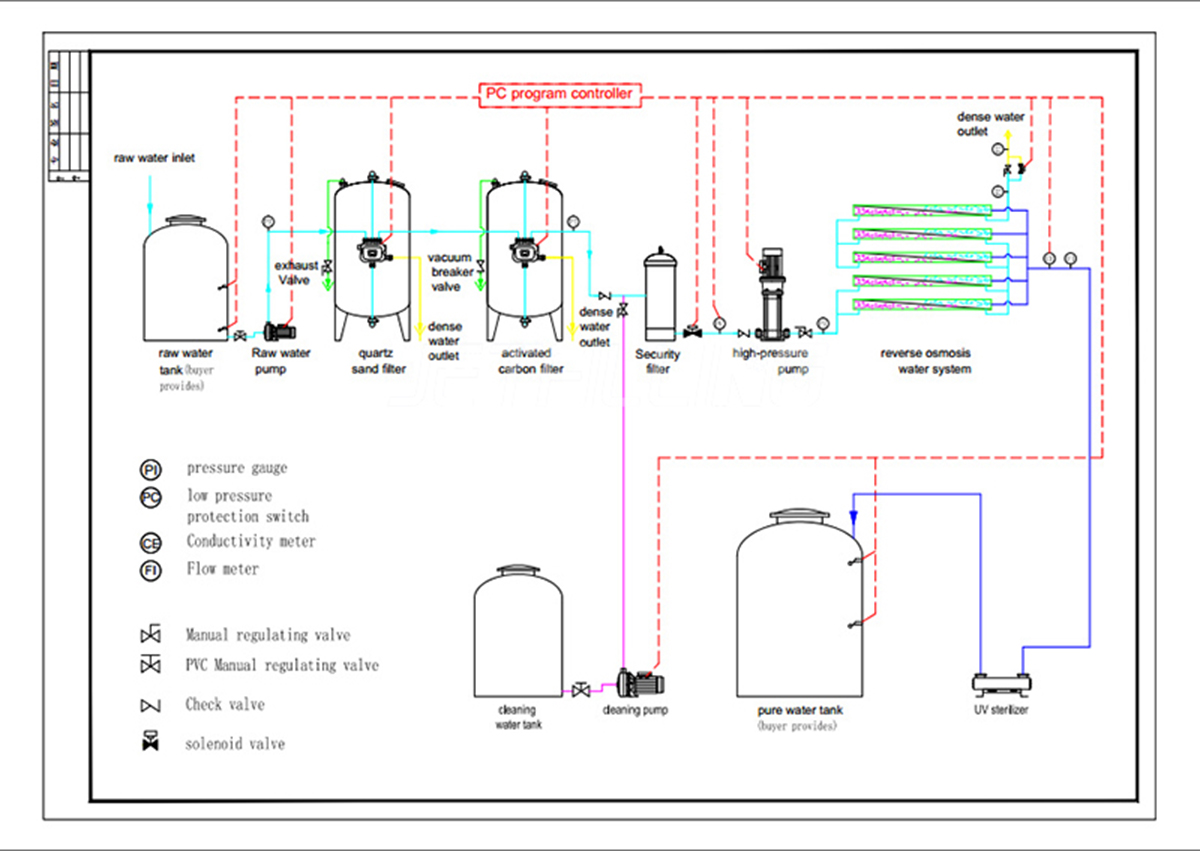

1. Raw water pump-- provide the pressure to quartz sand filter/active carbon filter.

2. Multi-medium filter-- get rid of turbidity, suspended matter, organic matter, colloid, ect

3. Active Carbon filter--Remove the color, free chloride, organic matter, harmful matter, ect.

4. Softener--exchange "ions" of calcium and magnesium with the most common and easiest method.

5. Micron filter--prevent large particles, bacteria, viruses into RO membrane, accuracy is 5um,

6. High pressure pump-- Provide the high pressure to RO membrane ro.

7. RO system-- main part of the plant. The RO membrane's desalting rate can reach 99%, removing over 99% ions.

|  |

Products Feature:

* High-precision filter, the aperture of nano-level, the best water quality

* Manual / electric control system automatically switch;

*With a self-test, water-free point automatically open the system of water, water full stop, no pressure protection and other safety devices;

*With open RO membrane automatic washing and water tank full automatic double wash function, can extend the life of RO membrane;

* With on-line monitoring of water quality (conductivity display), flow and pressure on-line display;

* Equipment integration, installation is simple, simple operation, no special duty;

*Equipment failure with automatic alarm function;

*High water production, high desalination rate, long service life;

* Core components (pumps, RO membrane, electronic control systems, etc.) imported / domestic joint venture brand;

* Equipment rack with stainless steel, low-pressure pipe for the UPVC material, high-pressure pipe using SUS304 stainless steel.

|

|

|  |

|

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

|  |  |

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.