Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

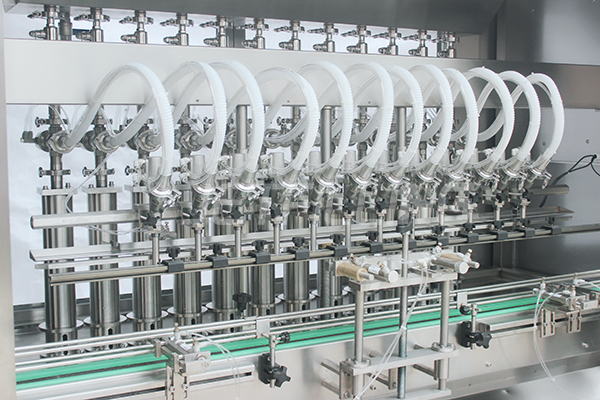

Filling machines work on the same basic principle, whether you are in need of a liquid filler for soap or an oil bottle filling machine. Our goal is to ensure no matter what type of liquid is inside, your machines are able to hold up to the pressure placed upon them. When in need of an auto oil filling machine or any other type of oil filling machine, we want to be the first name you think of due to our extensive line of machines and parts for whatever you need.

Oil Filling Machine

Filling machines work on the same basic principle, whether you are in need of a liquid filler for soap or an oil bottle filling machine. Our goal is to ensure no matter what type of liquid is inside, your machines are able to hold up to the pressure placed upon them. When in need of an auto oil filling machine or any other type of oil filling machine, we want to be the first name you think of due to our extensive line of machines and parts for whatever you need.

| Technical parameter :oil filling machine | ||||

| Model | FD-JE-oil | FD-JF-oil | FD-TE-oil | FD-SS-oil |

| Capacity | 1800BPH | 2500BPH | 4000BPH | 6000BPH |

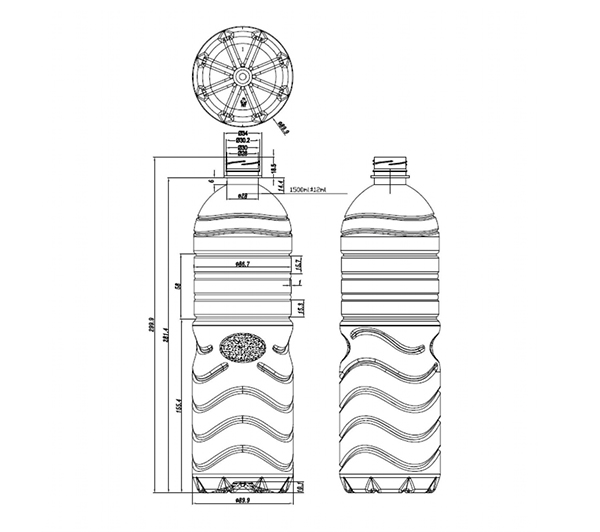

| Suitable bottle | Glass Bottle/PET Bottle | |||

| Bottle Volume | 0.1L~1L,1L~2L,1L~3L,1L~5L | |||

| Compressor air | 0.3-0.7Mpa | |||

| Air consumption | 0.37m3/min | |||

| Application | <0.4Mpa | |||

| Total power(KW) | 2KW | 2.5KW | 3.2KW | 3.5KW |

| Overall dimensions | 2750*1400*2150mm | 2750*1400*2200mm | 2750*1400*2300mm | 2800*1400*2300mm |

| Height | 2m | 2.2m | 2.5m | 2.6m |

| Weight(kg) | 1200kg | 1500kg | 1800kg | 2000kg |

Advantages:

* Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

* Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

* The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

* High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

* Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

| Anti Leakage filling valve Quantitative filling, adjustment for one key |

Volumetric filling piston No residual Angle for three-way valve, long service life.One key to clean residual material on steel sleeve. |  |

|  |

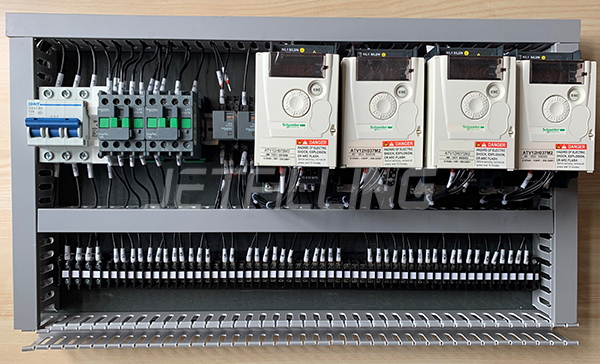

| Four groups of frequency converters control the cover divider, rolling wheel speed, conveyor belt speed and synchronous belt speed respectively, each part can be adjusted separately. | Cap lifter machine,automatic feed the cap. |

|

|

|  |

|

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

|  |  |

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.