Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

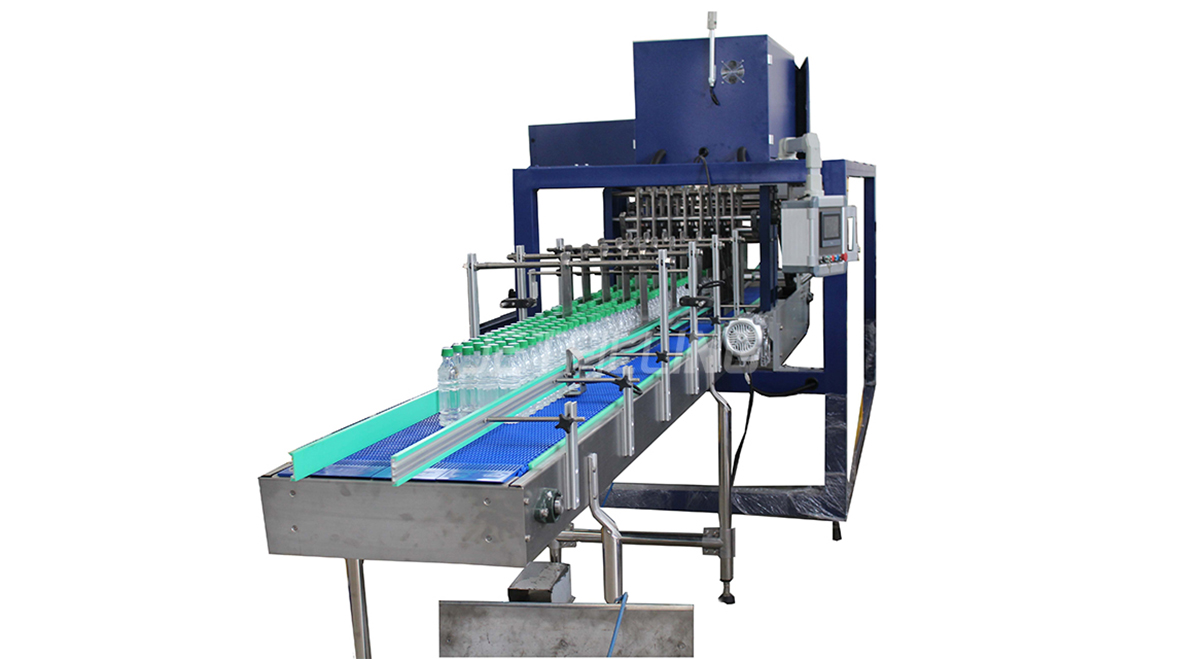

MBC200 High-speed heat-shrink packaging machine (printed film type) is based on the heat shrinkage characteristic of the packaging film. It uses photoelectric switch sensors to detect online, and the collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding. The bottle plate is arranged in a powerful manner, servo-controlled pushing bottles and wrapping into packages, heating channels shrinking, cold air cooling and shaping and other mechanisms to complete the entire packaging process.

Product Description

Linear PE Film Shrink Packing Machine

MBC200 High-speed heat-shrink packaging machine (printed film type) is based on the heat shrinkage characteristic of the packaging film. It uses photoelectric switch sensors to detect online, and the collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding. The bottle plate is arranged in a powerful manner, servo-controlled pushing bottles and wrapping into packages, heating channels shrinking, cold air cooling and shaping and other mechanisms to complete the entire packaging process.

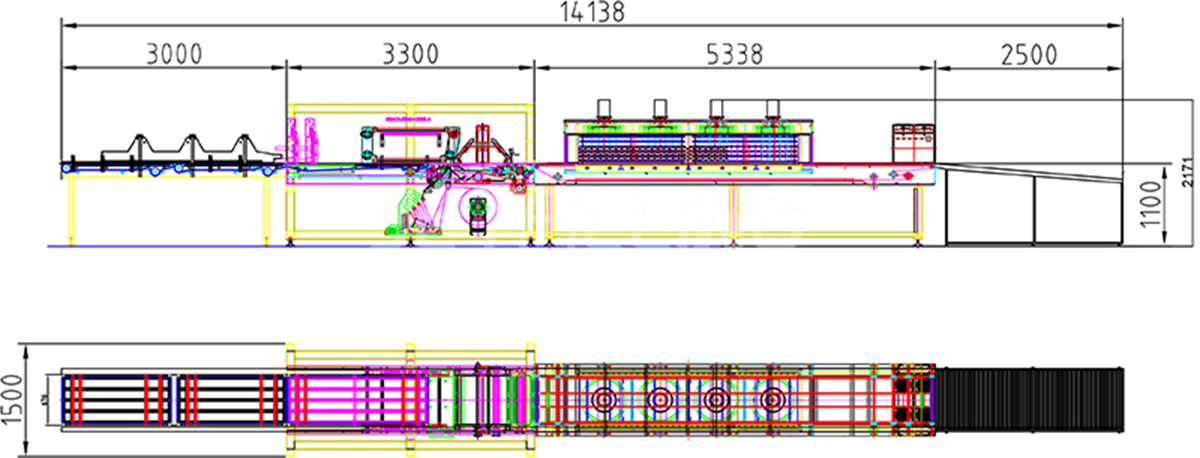

| Technical Parameter: | |

| Whole plant size | 14150*1500*2170mm |

| Bottle inlet and film wrapping part | L6300*W1500*H2100mm |

| Shrink tunnel part (include roller conveyor) | 7850*1100*2170mm |

| Shrinkage film material | PE |

| Suggested shrinkage film thickness | 0.07-0.15mm |

| Shrinkage tunnel max temperature | 180-220° adjustable |

| Max output per minute | 20-25 bags |

| Power | Heating shrink part(31KW) |

Product Description:

* Simple appearance, beautiful, novel structure, unique, easy maintenance.

* large-screen screen, the user interface LCD display in English.

* Pneumatic expansion support film roll, changing film quickly and quickly, for film only about two minutes.

* Film tension transmission, even formation, cutting film control precision, incision and tidy.

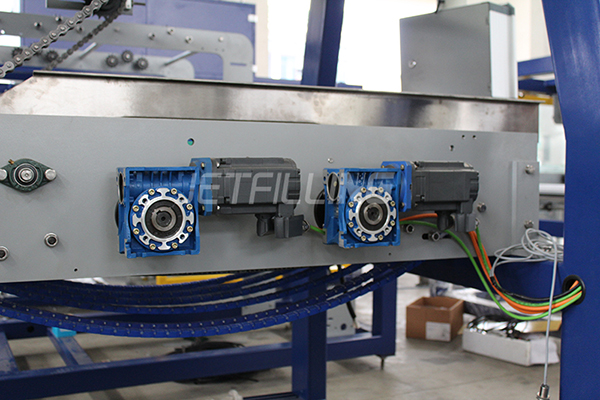

* advanced servo control technology to maintain accurate synchronization of the agencies, transmission and reliable.

* heating box structure is reasonable, thermal insulation, high temperature control accuracy.

* Supporting French Schneider, TAIWAN AIRTAC, South Korea AUTONICS ; the world's most advanced control components , well-equipped, condition and stability.

* mechanical transmission parts using heat-treated stainless steel or carbon steel and other materials; surface spraying excellent quality, the whole rust-proof performance.

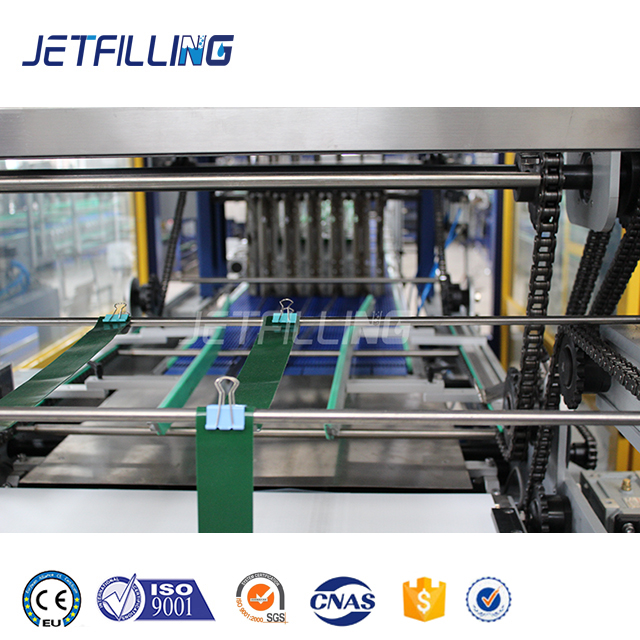

| Gate Type Bottles Divider |

Bottles Feeding Sorting Part |  |

| Conveyor Motor And Chain Transmission |

Tunnel And Fan Temp Control Unit |  |

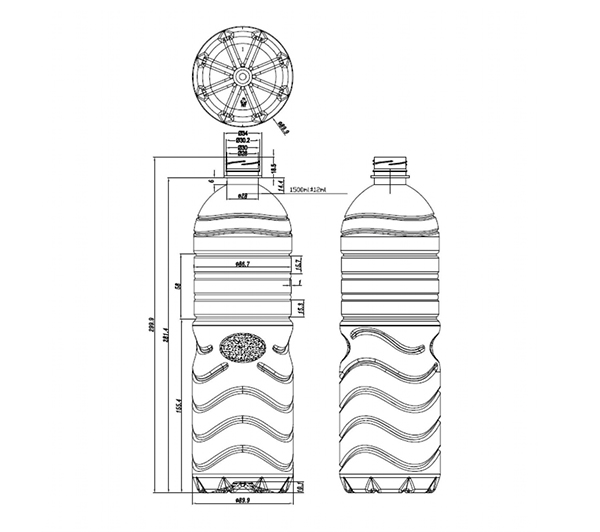

(1)350/500ML bottles package: 4×6, 4×5; 550/600ML bottles package: 3×4, 3×5.

(2)1L/1.5L bottles package: 3×3, 3×4; 2L/2.5L bottles package: 2×2, 2×3.

|

|

|  |

|

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

|  |  |

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.