Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

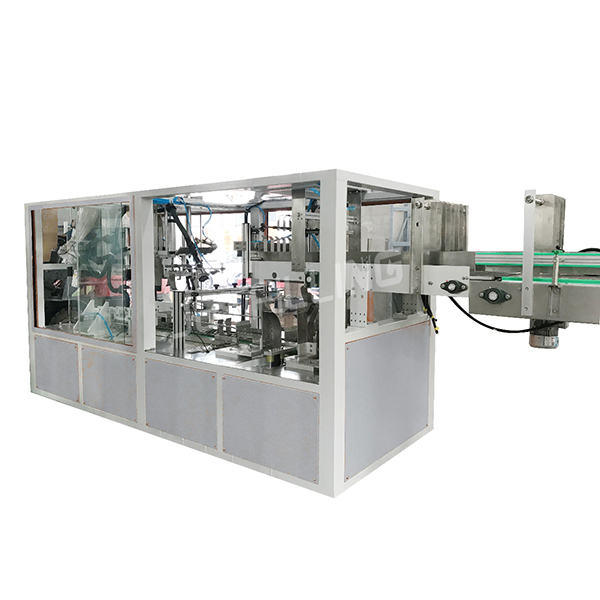

It carries out bottle washing filling and capping in one machine. The whole machine design is reasonable, appearance is beautiful, maintenance is convenient.It adopts hanging type conveying-bottle structure to make bottle size changing more convenient, faster and easier.The main machine adopts advanced PLC control technology. The key electric components adopt international famous products.

Beer Filling Machine

It carries out bottle washing filling and capping in one machine. The whole machine design is reasonable, appearance is beautiful, maintenance is convenient.It adopts hanging type conveying-bottle structure to make bottle size changing more convenient, faster and easier.The main machine adopts advanced PLC control technology. The key electric components adopt international famous products.

One partner for all your needs.

Beer filling machine from JETFILLING takes into account every step of your beer filling process, from minimising resource waste to determining your bottle's ideal look and weight. With everything centred around one supplier, you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.

| Technical parameter :beer filling machine | ||||

| Model | BGF12-12-4 | BGF18-18-6 | BGF24-24-8 | BGF32-32-10 |

| Capacity (500ml) | 1000BPH | 1500BPH | 4000BPH | 6000BPH |

| Suitable bottle | Glass Bottle/PET Bottle | |||

| Bottle Volume | 200ml~1L | |||

| Compressor air | 0.3-0.7Mpa | |||

| Air consumption | 0.37m3/min | |||

| Rinising pressure | >0.06Mpa<0.2Mpa | |||

| Application | Beer Filling Machine | |||

| Total Power(KW) | 3.5KW | 4KW | 5.5KW | 6KW |

| Height | 2m | 2.2m | 2.4m | 2.5m |

| Weight(kg) | 2000kg | 3500kg | 5000kg | 7000kg |

Different filling capacities:

| Washing Part Into bottle way is air conveyor direct connection with Bottle dial All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean. 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing. 304/316 stainless steel washing pump make the machine more durable. |

Filling Part 304/316 Stainless steel high precision flling nozzle. Filling volume adjustable in fine rank, same liquid level after flling. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean. 304/316 stainless steel flling pump. Efficient spray nozzle rinse thoroughly and save water for flushing. |  |

| Capping Part Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping. All 304/316 stainless steel construction. No bottle no capping. Automatic stop when lack of bottle. Capping effect is stable and reliable ,Defective rate≤0.2%. |

Filling Machine System

Including bottle washing&filling &capping system.

|

|

|

Labeling&Packing Part

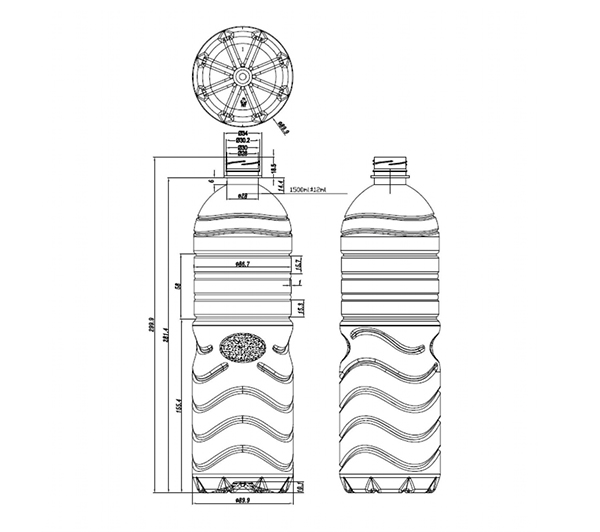

We can help customer design the different label choose for suitable bottle.Reduce costs for customers.

|  |  |

Shrink Sleeve Labeling Machine The shape is exquisite and beautiful, the overall structure is strong, and it is lighter and more flexible when used.The exclusive design of the reciprocating cutter adopts the rigidn body combination of the mechanism, the action is smooth. | Sticker Labeling Machine Advanced high torque micro-stepping driven applicators include ratio-offset and speed-following capability for accurate and reliable application of a wide variety of label materials. | OPP Hot Glue Labeling Machine This labeling machine is a fully automatic line- type machine for hot melt labeling, which is suitable for different container sizes and round bottle shapes. The system features high labeling accuracy with low glue consumption.Changeovers to different containers or labels are affected quickly and easy. |

|  |

Shrink PE Film Wrapping Machine Pneumatic expand support membrane roller, membrane change is quick.Membrane change just need two minute. Membrane tension transport, even and plat, film cutting controlling is precision. | Carton Packing Machine The equipment is positioned by private clothes, controlled by PLC and operated fully. The main rotations are driven by imported motors. All levels of rotations are regulated by chains and sprockets. It has the advantages of high automation, reliable control, simple adjustment and intelligent operation. It can be widely used in beverage, beer, chemical industry, food, medicine and other industries. It can be used for secondary packaging of various bottles and cans and matching with automatic filling production line. |

Bottle Blowing Machine

|

|

|  |

|

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

|  |  |

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.