Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

JET Sleeve Labeling Machine is custom built to meet the exacting demands of manufacturers and suppliers. It can be used stand alone or integrated in-line and matching filling equipment speeds.It is built upon a framework of seam welded, food grade stainless steel section. This solid foundation keeps movement and vibration to an absolute minimum to ensure consistent, accurate labeling.

Product Description

Shrink Sleeve Wrap Labeling Machine

1.JET Sleeve Labeling Machine is custom built to meet the exacting demands of manufacturers and suppliers. It can be used stand alone or integrated in-line and matching filling equipment speeds.

2.It is built upon a framework of seam welded, food grade stainless steel section. This solid foundation keeps movement and vibration to an absolute minimum to ensure consistent, accurate labeling.

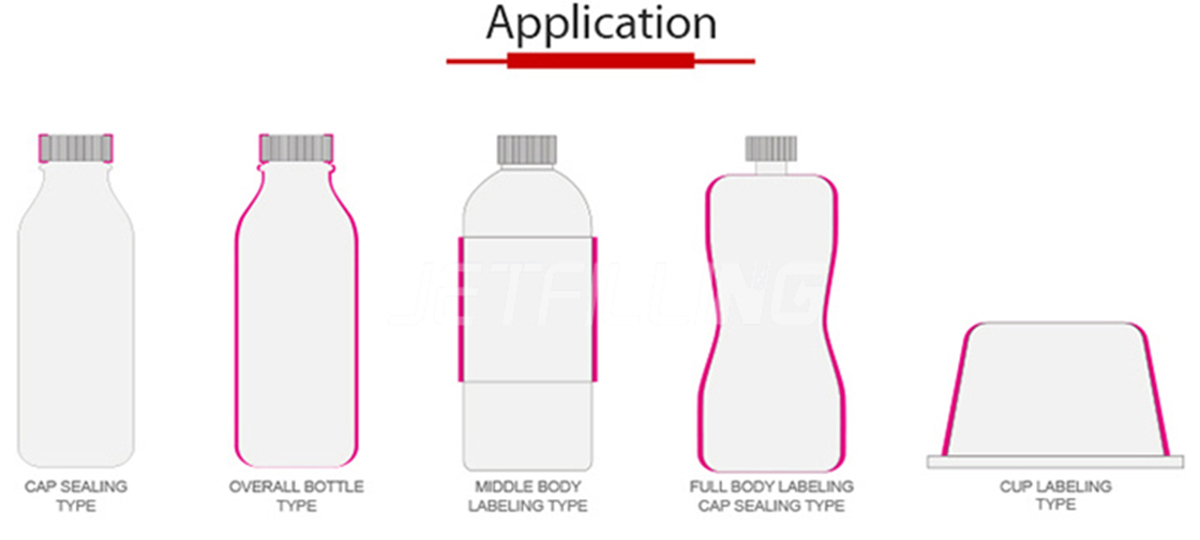

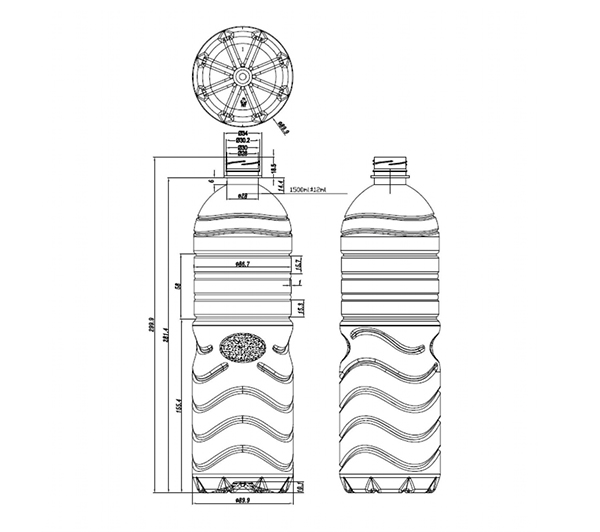

3. Unit cutter head plane design in China which apply to the container of ∮30 mm—∮130 mm. you never need to change or debug it. It also has unique light touch human-machine screen, that means, auto search original location as well as safety and convenience which is ahead of other congener products.

4. Double shrinking label feed plane, reasonable height which is convenience to fix the label; micro-computer auto figure which avoid enactment and adjustment. You only need to press it lightly ,the label will detect and locate automatically. The change of label is quick and convenience, besides, the cut place is absolutely exact.

5. The newly designed cutter stepper motor which speed is high ,action is exact, the cut is in order and the shrinking is beautiful. This design cooperate with the label synchronized location structure enable the precision of cut location within 1mm.

| Technical Parameter: | ||||

| Model | JET-150 | JET-250 | JET-350 | JET-450 |

| Length x width x height(mm) | 2400x1000x2200 | 2440x1000x2200 | 2540x1000x2200 | 2640x1000x2200 |

| Weight | 600kg | 600kg | 700kg | 800kg |

| Power | AC3-Phase 220V380V | |||

| Speed | UP to 150BPM | UP to 250BPM | UP to 350BPM | UP to 450BPM |

| Diameter | Φ50-Φ110 | |||

| Material | GLASS. METAI. PLASTIC | |||

| Shape | ROUND. OVAL. SQUARE. RECTANGLE | |||

| Material | PVC. PET. OPS. OPP | |||

| Thickness | 0.035-0.10mm | |||

| Label length | MAX150mm | MAX150mm | MAX200mm | MAX200mm |

| Label Fold the diameter | MAX175mm | MAX175mm | MAX175mm | MAX175mm |

Main Features:

*Whole machine frame is made out of stainless steel SUS304. The frame is simple, beautiful, waterproof and not rust. It is easy for cleaning.

*The special cutting system: adopting the whist and convoluted technology. The label cutting is flat, no burr.

*The label location set assures the sleeving veracity.

*Adopting model group design, module controlled; Achieve veracity and fast sleeving.

*With the good quality touching operation screen, achieving operation by finger, easy and shortcut.

*It is a high automatic packing machine. Just one person handles, easy operation.

*Easy to change packing material, the change over of the mould can be easily done by hand without any tools.

*Within the flat width limitation, can be used to package objects in different shape, no matter round or square, can be applied on glass or plastic bottles.

*Higher safely and stability for operation and saving time of manpower.

|  |

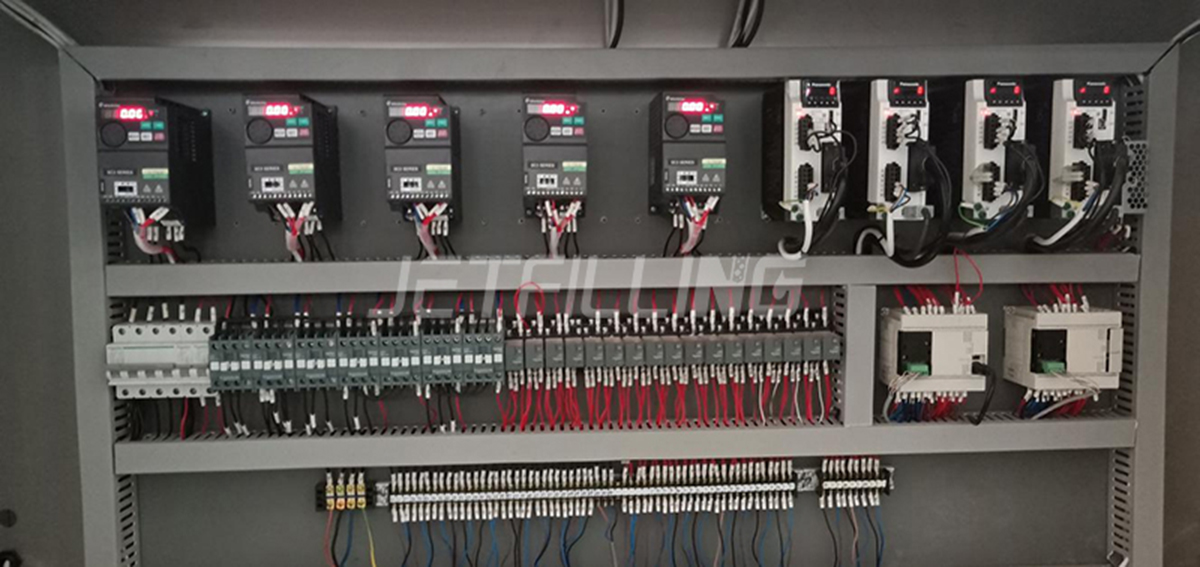

Internal structure of the machine for ref

Electrical configuration for ref

| Sleeve shrink tunnel for ref Made of SUS304 stainless steel. The equipment is with steam controller for steam blow wastage. Remained steam be brought out to plant through wind motor. Steam press is adjustable. Shrink effect is perfect and will |

Steam generator Advantages: |  |

|

|

|  |

|

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

|  |  |

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.