Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

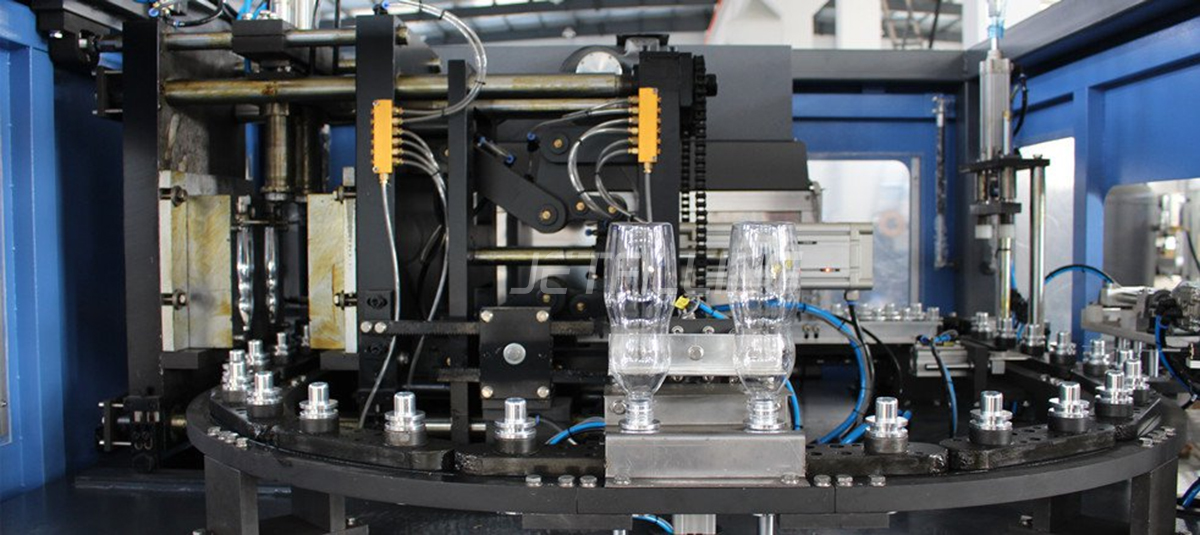

The automatic bottle blowing machine professionally produced by Jetfilling Machinery has advantages of high speed, good quality, high efficiency, better price performance and simple operation.

Blow Moulding System

The automatic bottle blowing machine professionally produced by Jetfilling Machinery has advantages of high speed, good quality, high efficiency, better price performance and simple operation.

Operation Specification:

1) Before each shift starts, lubricating oil must be added to the moving parts once (manipulator, manipulator rail, opening and closing mold rail, etc.).

2) Swing arm can be added once a week, and large chain and small chain of heating machine can be added once a month. Check regularly whether the reducer of the host machine and the reducer of the heating machine are short of oil. The bearing of the host machine can be added once every three months.

3) Before production, check whether the moving parts are firm, whether the screws are loose and fall off, especially where the impact force is strong and whether the transmission part is abnormal.

4) Check whether high pressure air source, low pressure air source, power supply and water source are normal.

5) check the emergency stop switch, safety door switch, protection device to detect whether the switch is normal.

6) Check whether the heating head, upper embryo and embryo dropping part work normally.

7) check whether the lamp is damaged, broken, if there is abnormal need to be replaced in time.

8) Check whether the pneumatic components leak and whether the action is sensitive.

9) When the magnetic valve of the automatic bottle blowing machine is abnormal, it should be cleaned in time (3.5 million yuan for each bottle blowing).

Supply bottle&label design and factory layout for free!

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

Factory Manufacturing

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.