Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

Highest quality, lowest budget, complete turnkey project are the benefits for the customer.

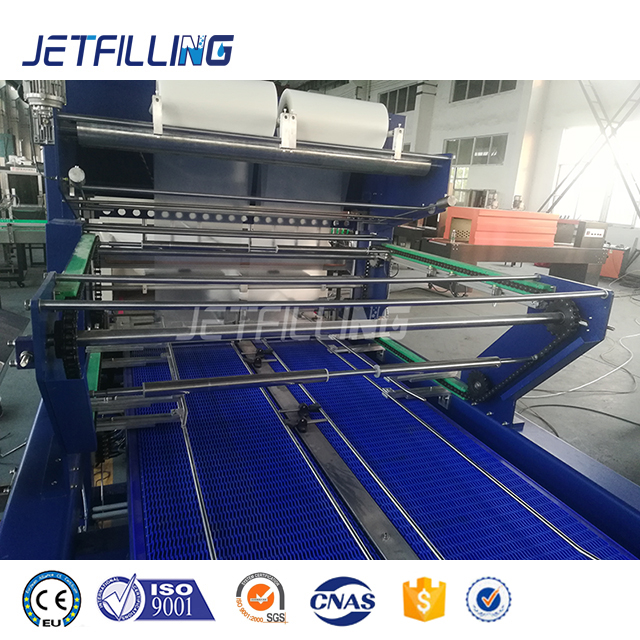

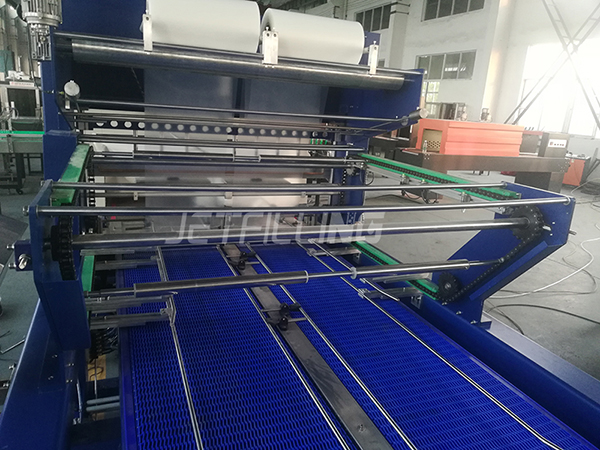

Automatic PE Film Shrink Packing Machine is suitable for wrapping pop-cans, bottles, etc, both with bottom-tray and without bottom-tray, working with PE shrink tunnels. The machine adopts the Germany advanced technology and international famous brands, which makes capability stable and using long-time.Apply for the beer, drinking, mild, food.Automatic bottle Distribute and block,customized packing. High automatically suitable unit or lined.reduce operator cost. Control by PLC,operating through touch monitor pamel.Compacr layout and easy service or miantenance. Adjustable speed,customized bottle layout,fast and easy changing the mould.

Product Description

Plastic Bottle PE Film Shrink Packing Unit

Our shrink packing machine is made of bottle loading system, packing machine, thermo-shrinking machine, no-drive roll convey machine and electric control system, pneumatic control parts and so on.Produce process: MUL350 automatic linear packing machine is produced at the basis theory of the film shrinking after heated. The whole packing process is including photoelectric sensor testing, PLC treats the collected signal, convey belt delivering the bottles, the dividing board divide the bottles into lines and the push the bottles to be filmed, the thermo-sealing knife seal the film into bags, the cooling tunnel cool the bags. Shrink Wrap machine for Pet , Glass , HDPE bottle, Tin Group Shrink Packing machine, bundling packing machine.

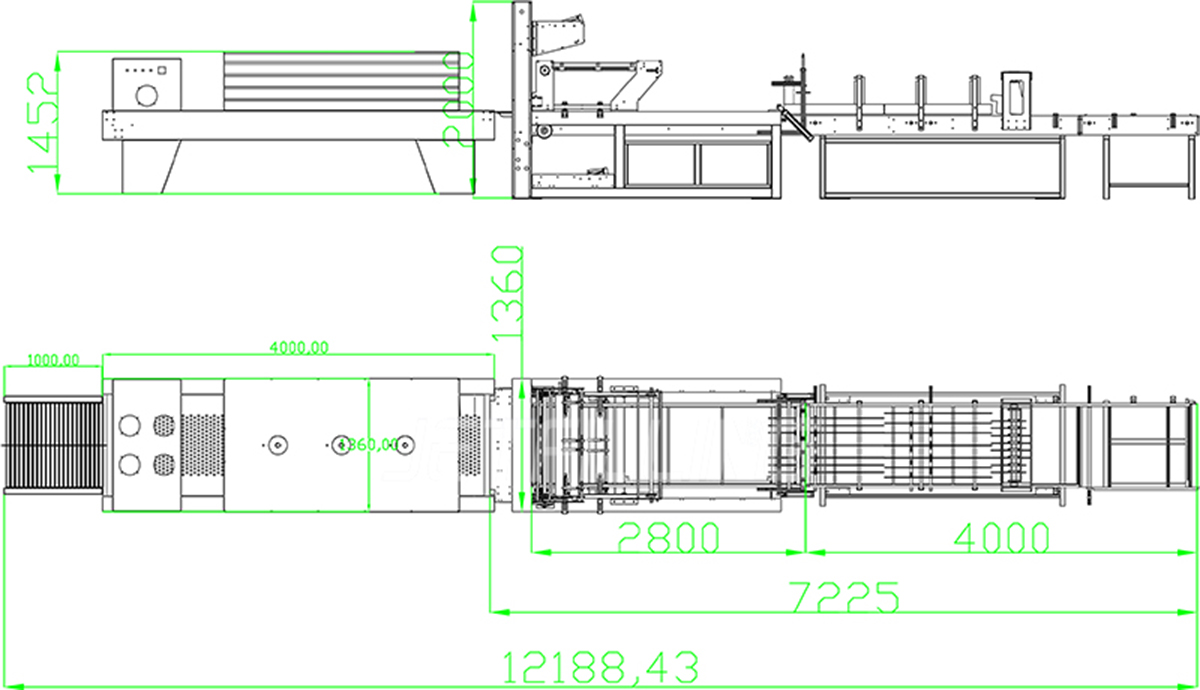

| Technical Parameter: | |

| Facility overall size | 12200*1360*2000mm |

| Shrinkage film material | PE |

| Shrinkage film thickness | 0.03-0.15mm |

| Thermo shrinkage tunnel max temperature | 160-260°adjust at will |

| Max output per minute | 30-40 bag |

| Facility power | 53KW |

| Pressure requirement | 380V/50-60HZ |

| Facility weight | 3000kg |

| Air pressure | 0.6-0.8mpa |

| Working noise | ≤65db |

| Import bottle convey belt width | 926mm |

Product Description:

* frequency converter speed adjust、two segment convey

* Bottle pushing, thermos sealing and cutting whole movement adopt to pneumatic

* Proximity switch control film

* Touch screen, PLC system greatly increase facility movement

* double-wind recycle fan machine, ensure shrinkage tunnel inside even

* super big wind-volume cooling system, ensure quickly get into shape.

* anti-high temperature Teflon convey belt, convey steadily, high-strengthanti-abrasion.

* frequency limitless speed adjust convey belt

* convey belt height can make according client requirement, adjustrange:±50mm

* bottle convey machine can meet with client bottle forward direction requirement, can lengthen or shorten.

* wing stainless steel heating system,

* meet with product instant stop requirement product-bearing rack device ensure production line consistency.

| Shrink Film Roll Unit(Upper Part) |

Bottles Sorting Cylinders(AIRTAC) |  |

| Siemens Touch Screen Control Panel |

Shrink Film Roll Unit(Below Part) |  |

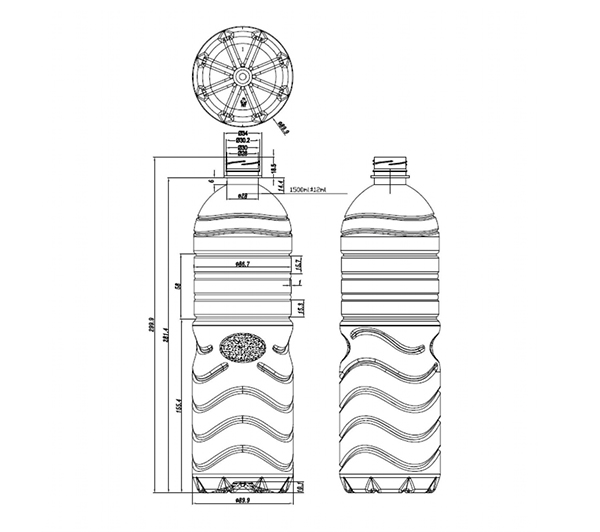

(1)350/500ML bottles package: 4×6, 4×5; 550/600ML bottles package: 3×4, 3×5.

(2)1L/1.5L bottles package: 3×3, 3×4; 2L/2.5L bottles package: 2×2, 2×3.

|

|

|  |

|

Containerization – International shipments require greater care and protection than domestic shipments. As an important factor in the global trade industry, containerization protects the shipment inside the container from humidity and extreme freezing temperature. The benefits of containerization include:

1.Reduced loss and damage cost 2.Lower transportation and warehouse cost due to easy storage and transportation of containers 3.Can be used to temporarily store your equipment

|  |  |

Half-finished products and spare parts are well prepared

Mass production of semi-finished products and parts can ensure that the equipment required by most customers can be completed within one month!

|  |

The whole production will be connected and test running in factory

Before leaving the factory, each device will be tested many times to ensure that there is no problem with each device that customers get!

By continuing to use the site you agree to our privacy policy Terms and Conditions.